Plastic Injection Molding

Are you tired of working with plastic injection suppliers only for the product quality and price to disappoint you? If so, turn to us at Offshore Direct Metals, one of the leading plastic injection molding companies serving customers throughout the world. With a broad range of plastic parts and components, we assist all types of industries, including consumer, electrical, plumbing, electronics, automotive, and more. A key benefit of using us as your source for custom plastic injection molding is the fact that we offer products in multiple plastics, such as HDPE, acrylic, PET, nylon, polypropylene, polyurethane, polysulfone, and more. Regardless, all our injection molded parts and components meet a tight tolerance up to .0005. AS a top-rated plastic injection molding manufacturer, we have several unique offerings. We can inspect our customer’s supplied part database or use blueprints that you provide. We also have CNC services, EDM wire and sinker services, product samples, assembly and packaging services, and prototyping. Another reason we outperform other plastic injection molding companies is that we use only state-of-the-art machinery with capabilities from 50 to 500 tons maximum part weight and size. For superior-quality plastic products, Offshore Direct Metals is the best plastic injection molding manufacturer.

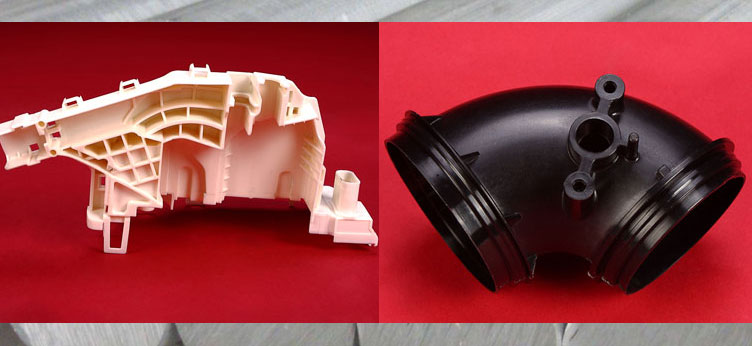

We are a plastic injection molding supplier of a wide range of plastic products and parts.

Industries Served: Automotive, Consumer, Electrical, Electronics, Plumbing.

Benefits of Plastic Injection Molding?

Benefits of Plastic Injection Molding?

- Efficient Production: when you work with a reliable plastic injection molding company, the production of plastic injection moldings is fast and easy to forecast.

- Complex Design: Plastic injection moldings can be designed to handle complex and intricate designs for maximum customization and optimized performance.

- Color & Material: To best suit your application, the color and material of plastic injection molding components can be altered to your choosing.

- Reduce Costs: Partnering with a plastic injection molding company such as Offshore Direct Metals enables you to reduce labor and manufacturing costs to boost profitability.

Materials

- ABS - Acrylonitrile-Butadiene-Styrene

- Acetal

- Acrylic

- HDPE - High Density Polyethylene

- Nylon

- PBT - Polybutylene Terephthalate

- PC - Polycarbonate

- PEEK - Polyetheretherketone

- PET - Polyethylene Terephthalate

- Phenolic

- Polyester

- PP - Polypropylene

- PPE - Phenylene Ether Co-polymer

- PPS - Polyphenylene Sulfide

- PS - Polystyrene

- PSU - Polysulfone

- PUR - Polyurethane

- PVC (Terpolymer)

- TPU - Thermoplastic Polyurethane

Tolerance

- Up to .0005

Inspection

We, as a top plastic injection molding supplier, have the ability to inspect customer supplied part databases, with complex contoured surfaces or we can use your blueprints to inspect with. We provide a full service inspection that includes capabilities studies, gauge R&R's and 100% part inspection.

Secondary Operations

CNC Services, Complete Mold and Die Repair/Rebuild Services, Contract Manufacturing, EDM Wire & Sinker Services, Product Sample, Production Assembly and Packaging Services, Prototype

Capabilities

Our plastic injection molding machines capabilities are from 50 tons to 500 tons, max. part weight and sizes we can produce are as follows:

- 500T 1200g 800x600mm

- 420T 800g 700x550mm

- 350T 650g 550x450mm

- 250T 300g 300x250mm

- 180T 250g 200x150mm

- 150T 200g 150x100mm

- 120T 150g 150x100mm

- 100T 150g 150x100mm

- 80T 120g 100x80mm

- 50T 100g 100x80mm

Why Choose Us For Plastic Injection Molding

Offshore Direct Metals is a premium plastic injection molding company known for quality and exceptional service that helps businesses across the country reduce overhead costs and streamline operations. You can enhance manufacturing when you choose Offshore Direct Metals for plastic injection molding design and production. Our designers and engineers can help you select the optimal plastic materials for your applications.

- High-Quality: From materials to design and manufacturing, at Offshore Direct Metals, we ensure that our plastic injection moldings deliver on your expectations and performance.

- Customizable: We use your blueprints, applications, and performance requirements to customize plastic injection moldings to your unique needs for the best results tailored to your offering.

- Expertise: Offshore Direct Metals has been a thriving and trusted plastic injection molding company for many years. We’ve honed in our practices and are ISO compliant, delivering the best plastic injection molding worldwide straight from the factory floor.

- Materials: Depending on your application, we offer plastic injection moldings in a variety of materials, including but not limited to acrylic, nylon, and polyurethane, to maximize durability and functionality.

- Technology: For manufacturing, inspections, assembly, and packaging, we use advanced technology and machinery to deliver on our promise of quality and streamline production for maximum convenience and reliability.

- Industries Serviced: With an extensive range of plastic material options and state-of-the-art technology and equipment, Offshore Direct Metals is a plastic injection molding company equipped to customize plastic injection molding to industry-specific standards allowing us to confidently service a wide variety of industries from automotive and electrical to plumbing, electronic, and consumer products.

For the best in plastic injection molding and more, contact Offshore Direct Metals.

Certifications

- Certified to ISO9001:2008