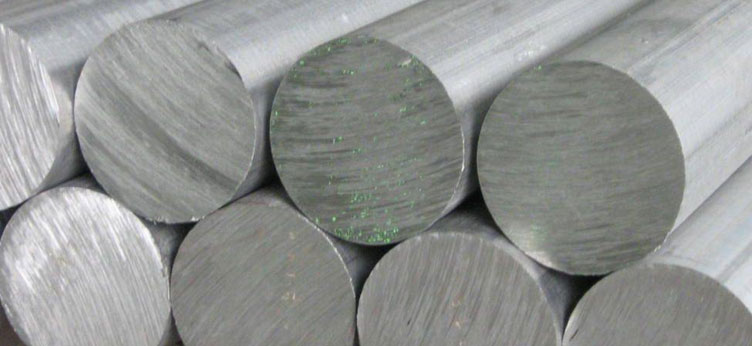

Aluminum Billets and Ingots

Aluminum Billets and Ingots are intermediate castings which are to go through further processing before the finished good is produced.

As one of the top aluminum billets suppliers, we guarantee a superior-quality product that you can use for additional processing needs such as extrusion, continuous casting, centrifugal casting, and ingot or bloom hot rolling. In situations when you need precise metallurgical structures, we surpass our customers’ needs, allowing them to manufacture final products of outstanding caliber. At Offshore Direct Metals, we take immense pride in serving customers as one of the most trusted aluminum billets suppliers. Our goal is to deliver products of high quality quickly and at an affordable price. We accomplish that by shipping directly from the factory to the customer’s door, using state-of-the-art extrusion and injection molding machinery and streamlining processes. As one of the leading aluminum billets suppliers in the United States, you can select from a broad range of sizes, perfect for any scenario. Contact us today for one-on-one assistance.

How Aluminum Billets are Created

Aluminum Billets usually have a round or square cross-section and is created through:

- 1. Continuous casting

- 2. Extrusion

- 3. Ingot or bloom hot rolling

- 3. Centrifugal casting

They are used when precise metallurgical structures are required. They can be prepared from recycled Aluminum and also from ingots, which are a purer form. If the billets are soft in nature, then its alloy is coupled with other types of metals for the purpose of machining. It is very important that the billets, used in the molding, are of superior quality in order to ensure that the final product is also of high quality.

Why Choose Offshore Direct Metals

Offshore Direct Metals is one of the most prominent Aluminum billet manufacturers in the USA. We are a global B2B trading company and put immense stress on the quality which we provide to our customers.

We are also proud to present our customers with significant reductions in the cost of their supply.

During tough times, maximizing the use of every dollar becomes paramount to everyone in business. It is no different for our customers looking to buy Aluminum billet at more competitive prices than what is available in the domestic market.

We use state-of-the art extrusion and injection molding machinery to provide you with high quality materials for your production at competitive prices.

Our annual capacity of homogenized Aluminum alloy billets is 180,000 tons.

Available diameter sizes: 3”, 3.5”, 4”, 4.5”, 5”, 5.5”, 6”, 7”, 8”, 9”, 10”, 12”, 14”, 16”