How Custom Aluminum Extrusions Compare to Plastic Injection Molding

Businesses and manufacturers rely heavily on component parts such as custom aluminum extrusions to assemble and create essential equipment and accessories used in everyday life and many unique industries. Advances in technology and these varying manufacturing processes allow for the production of highly customized parts for virtually any application.

So when contacting an aluminum and plastic injection molding supplier, how do you choose the best option for your needs?

Read on to compare custom aluminum extrusions with plastic injection molding.

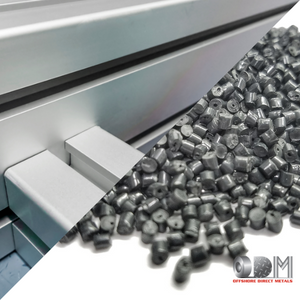

What is Plastic Injection Molding?

Plastic injection molding is used to mass-produce component parts for different uses and industries. A custom mold is designed by plastic injection molding suppliers to fit the specification of your project. Plastic pellets are liquified and injected into the molding to produce the required component part. Some of the most commonly used plastics by plastic injection molding suppliers are thermosetting polymers and thermoplastic polymers. The best material is chosen based on the performance demands of the final product. To determine the best plastic polymer for your order, contact the OD Metals team directly.

Plastic injection molding is used to mass-produce component parts for different uses and industries. A custom mold is designed by plastic injection molding suppliers to fit the specification of your project. Plastic pellets are liquified and injected into the molding to produce the required component part. Some of the most commonly used plastics by plastic injection molding suppliers are thermosetting polymers and thermoplastic polymers. The best material is chosen based on the performance demands of the final product. To determine the best plastic polymer for your order, contact the OD Metals team directly.

Industries & Applications of Plastic Injection Molding

Plastic injection molding is used to produce components in the construction industry, medical industry, retail, windows, doors, and more. Our team of plastic injection mold suppliers uses the process to create fasteners, food & beverage containers, keyboards, industrial fittings, surgical products, dental kits, product stops, window handles, locks, screen corners and more.

Benefits of Plastic Injection Molding

Plastic injection molding is chosen for many reasons. The high-quality materials are stable and durable, even when exposed to the elements. They’re also lightweight, affordable, energy-efficient, and highly customizable.

What are Custom Aluminum Extrusions

Custom aluminum extrusions are made by taking aluminum and pushing it through a custom die or mold. This process creates a cross-sectional profile, creating highly-functional parts with desirable qualities.

Industries & Applications Aluminum Extrusions

As a leader in North America, OD Metals has produced custom aluminum extrusions for many industries. Aluminum extrusions can be found in everyday spaces such as stores, schools, automobiles, boats, hospitals, etc. They can also be found in more specialized industries, such as the aviation, marine, and space industries. Some specific uses of custom aluminum extrusions include railings, window frames, roof rails, engine blocks, and more.

Benefits of Custom Aluminum Extrusions

In addition to being customizable, aluminum extrusions from OD Metals offers numerous highly sought-after advantages. Aluminum is a sustainable material that reduces the ecological footprint of businesses that use it in their products. The metal also is corrosion-resistant, durable, and lightweight, offering a high weight-to-strength ratio, making it perfect for demanding applications. Custom aluminum extrusions do not easily spark. As such, they are excellent thermal and electrical conductors.

Choosing Offshore Direct Metals

At OD Metals, we have all your plastic injection molding, and custom aluminum extrusion needs covered. Get started on your next order easily when you contact North America’s trusted extrusion and plastic injection molding suppliers today.

1.855.272.3889

1.855.272.3889  1.365.697.5889

1.365.697.5889