Benefits of Using Thermoplastics

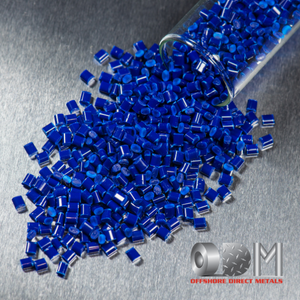

Thermoplastics are a type of polymer material that has become increasingly popular in manufacturing due to their unique properties and advantages. Plastic extrusion companies and injection molding suppliers using thermoplastics for a wide range of industries, from aerospace and automotive to packaging and construction. Offshore Direct Metals is leading injection mold supplier and plastic extrusion company providing businesses and manufacturers across North America with high-quality materials.

Explore the benefits of using thermoplastics in manufacturing across industries.

Versatility

One of the key benefits of thermoplastics is their versatility. They can be molded and shaped into different forms, sizes, and designs, making them ideal for use in a wide range of applications. They can also be used in combination with other materials, such as metals, to create complex components. This versatility allows injection molding suppliers and plastic extrusion companies to create products that are tailored to the specific needs of their customers, whether it's a lightweight and durable automotive part or a specialized medical device.

One of the key benefits of thermoplastics is their versatility. They can be molded and shaped into different forms, sizes, and designs, making them ideal for use in a wide range of applications. They can also be used in combination with other materials, such as metals, to create complex components. This versatility allows injection molding suppliers and plastic extrusion companies to create products that are tailored to the specific needs of their customers, whether it's a lightweight and durable automotive part or a specialized medical device.

Lightweight

Thermoplastics are generally lightweight, which makes them ideal for use in applications where weight is a concern, such as in the aerospace and automotive industries. For example, thermoplastic composites are used in aircraft interiors and structural components, which reduces weight and improves fuel efficiency. The use of thermoplastics in automobiles can also help reduce weight and improve performance, as well as reducing emissions.

Chemical resistance

Thermoplastics are resistant to a wide range of chemicals, making them suitable for use in industries where exposure to chemicals is common, such as in the pharmaceutical and chemical industries. They can withstand exposure to harsh chemicals, acids, and bases without degrading or losing their properties, which makes them a durable and long-lasting material. This chemical resistance also makes thermoplastics an ideal choice for packaging materials for food and beverages.

Durability

Thermoplastics are known for their durability, which makes them ideal for use in applications where strength and toughness are important, such as in construction, packaging, and electronics. They can withstand high impact and are resistant to wear and tear, making them an ideal choice for products that need to withstand harsh conditions. For example, thermoplastic pipes are commonly used in the oil and gas industry because of their durability and resistance to corrosion.

Recycling

Thermoplastics can be easily recycled, making them an environmentally friendly choice for manufacturing. This also helps reduce waste and save resources. When thermoplastics are recycled, they can be melted down and re-molded into new products without losing their properties, which makes them an ideal choice for products that need to be reused or recycled.

Cost-effective

Thermoplastics are generally cost-effective compared to other materials, which makes them a popular choice for manufacturers looking to reduce costs without compromising on quality. They are also easy to manufacture and can be produced in large quantities, which further reduces costs.

The benefits of using thermoplastics in manufacturing across industries are numerous. They offer versatility, lightweight, chemical resistance, durability, recycling, and cost-effectiveness, making them a popular choice for a wide range of applications. As technology continues to improve, we can expect to see even more innovative uses for thermoplastics in the future.